Todos os Produtos

-

Peças de moldagem por injeção de metal

-

Partes de moldagem por injecção de pó

-

Peças da metalurgia de pó

-

Partes metálicas sinterizadas

-

Partes de usinagem CNC

-

Partes de máquinas de torneamento, moagem ou moagem

-

Acessórios de Airsoft da AEG

-

Partes de caixa de engrenagens de armas de airsoft

-

Ferramenta de chaveiro exterior

-

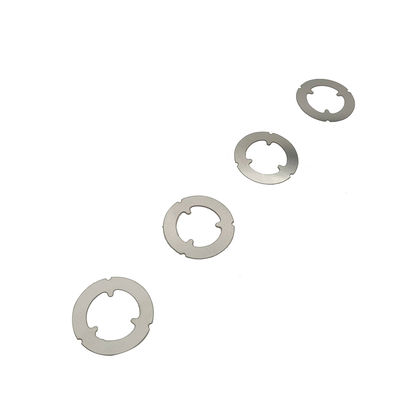

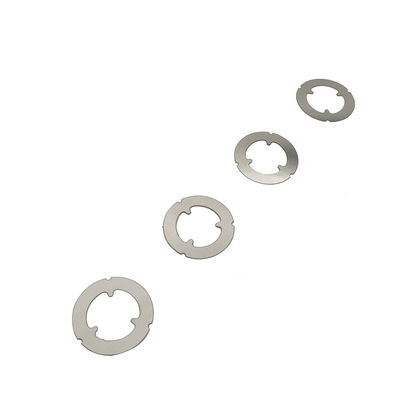

Flat Gasket Shim e Lavadoras

Customized Laser Cutting Stainless Steel Flat Washer Adjustment Shims with 2 Years Warranty and 0.02mm Tolerance

| Lugar de origem | Guangdong, China |

|---|---|

| Marca | MDM |

| Documento | Folheto PDF do produto |

| Quantidade de ordem mínima | 1000 |

| Preço | $0.02-0.04 |

Contacte-me para amostras grátis e vales.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

xDetalhes do produto

| Material | Aço inoxidável | Revestimento | Zinco |

|---|---|---|---|

| Peso | 0,01 kg | Tratamento de superfície | Anodizando |

| Tolerância | 0,02mm | Método de processamento | Ferramentas de máquinas CNC |

| Rugosidade da superfície | Ra 0,8-3.2 | Technics | Máquinas de torneamento/moagem/usinagem/perfuração/corte a laser/estampagem/corte de fios |

| Tamanho | Tamanhos personalizados aceitáveis | Cor | Cores personalizadas |

| Opções de material | Alumínio 6061/7075, aço inoxidável 304/316/420/303, latão, cobre, titânio, aço carbono, aço leve, aç | Opções do tratamento de superfície | Revestimento de zinco, revestimento de cromo, revestimento de níquel, revestimento PVD, anodização, |

| Opções de cores | PVD preto/prata/dourado/dourado, óxido preto, galvanização de zinco preto/prata/colorido | Quantidade de ordem mínima | 100 |

| Embalagem | Saco poli + caixa interna + caixa | ||

| Destacar | 2 Years Warranty Flat Washer,0.02mm Tolerance Adjustment Shim,100% QC Inspection Shim Washer |

||

Descrição de produto

Customized Laser Cutting Stainless Steel Flat Washer Adjustment Shims

Precision-engineered flat washer adjustment shims manufactured through advanced laser cutting technology for perfect fit and dimensional accuracy.

Product Specifications

| Material | Aluminum 6061/7075, stainless steel 304/316/420/303, Brass, copper, Titanium, Carbon steel, Mild steel, #45 steel, 4140, 4340, Kovar alloy |

| Surface treatment | Original or customized options including zinc plating, chrome plating, nickel plating, PVD coating, anodizing, polishing, sand blasting |

| Technics | CNC Turning/milling/machining/drilling/laser cutting/stamping/wire cutting |

| Sample | Sample costs refundable upon mass production confirmation |

| Surface Roughness | Ra 0.8-3.2 |

| Color | PVD black/silver/yellow/golden, black oxide, zinc plating black/silver/colorful etc. |

| Feature | Premium quality, 100% inspection before shipping, 2-year sales guarantee |

Company Profile

Dongguan Minda Metal Technology Co., Ltd., founded in 2015, specializes in precision manufacturing of CNC machining parts, MIM components, powder metallurgy parts, and aluminum/magnesium alloy die casting products. We also provide comprehensive mold design, development, and production services.

Our professional sales team maintains constant communication to understand customer requirements, which are promptly relayed to our technical staff. Our general manager provides rapid, accurate quotations tailored to your specific needs.

Throughout production, we implement rigorous quality control measures. Every product undergoes comprehensive inspection prior to shipment to ensure zero defects reach our customers.

With our expertise and your requirements, we provide complete hardware accessory solutions. Contact us anytime - we're available 24/7.

Packaging & Shipping

Frequently Asked Questions

Q1. What kind of documents do you need for a quotation?

A: We require PDF drawings or 3D files in STEP, IGS, or X_T format for accurate quotations.

Q2. Can you make the parts according to samples?

A: Yes, we can reverse engineer parts from physical samples. We'll create precise CAD models from your samples for production.

Q3. What kind of materials are used on your products normally?

A: We work with various materials including Aluminum, Steel, Brass, Stainless Steel, Bronze, and Titanium alloys.

Q4. Can you assemble the products?

A: Yes, we provide complete assembly services according to your specified requirements and assembly drawings.

Produtos recomendados